Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with D.R. EQUIPMENT SERVICES LIMITED!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

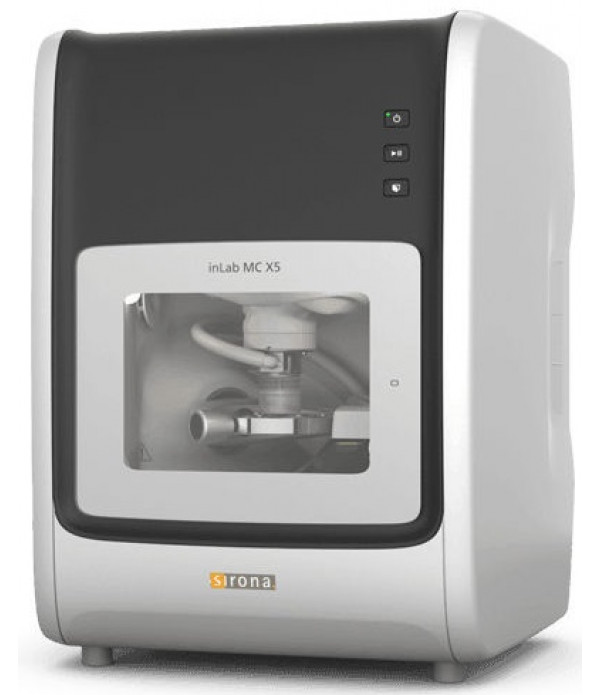

Sirona inLab CEREC MC X5 5-Axis Dental Milling Machine

Shipping terms: CIF (5-6 days world-wide delivery)

Payment method: Bank t/t,Bitcoin,Money Gram,Western union & Ria

Insurance fee: To be calculated after order processing

Warranty: 2-Years

MOQ: 1 Piece

Technical Data:

- Dimensions629 mm x 575 mm x 795 mm

- Weight87 kg

- Wet GrindingYes

- Number of Axes5

- Spindle SpeedMax. 60,000 rpm

- Automatic Tool ChangingYes

- Material CompatibilityZirconia, Polymer, Wax, Composites, Glass Ceramics, Hybrid Ceramics, Metals

- Material SizeBlocks in sizes I8 to B40L with specialized block holder capable of holding 6 blocks size I14/C14

Discs 98 mm diameter x up to 30 mm height - ArchitectureOpen

Open:-

inLab MC X5 is a completely open production unit. It is the perfect supplement to the inLab components inEos X5 and inLab software, but for the first time it can also be used to process other STL restoration data.1 The completely redeveloped CAM module enables the machine to be connected to a wide range of other CAD systems at no additional cost.

Great variety of materials:-

inLab MC X5 is designed as a universal production unit for processing zirconium oxide, polymers, composites, wax and metals2 as well as glass and hybrid ceramics.

Disks and Blocks:-

inLab MC X5 processes standard disks (Ø 98.5 mm, up to 30 mm thick)3 and blocks in a single machine. Together with complete freedom to use any material, the system offers you the capability to handle a broad spectrum of indications today and in the future. Switching from disks to blocks takes just a few seconds.

The innovative multi-block holder can accommodate up to six blocks of different materials thereby enabling maximum productivity even with multiple single tooth applications.

Wet and Dry:-

inLab MC X5 can be used for wet, dry, or dry/wet combination production during the same machining operation depending on material and indication.

Sirona has drawn upon its 30 years of experience in the wet processing of glass ceramics to create the ultimate machine for the wet grinding of fully anatomical restorations from high-strength monolithic materials.

Switching between wet and dry production e.g. from glass ceramics to zirconium oxide is fast and uncomplicated.

Milling and Grinding:-

Different tools are used depending on whether the machining process is wet or dry: Our carbide cutters and diamond grinders are designed to ensure that the cutting geometries and coatings are optimal for various indications and materials. So you achieve superb results on all surfaces and margins.

Spindle Touch Technology:-

The unique technology of inLab MC X5 is able to capture the position of disks and blocks with the utmost precision. These exceptionally high levels of accuracy enable you to make the most economical use of materials and e.g. efficiently machine blocks with dentin or mesostructures.4

First-Class Tool Changing Concept:-

The fully automated tool changer can be fitted with up to six tools per process. You can prepare the tool magazine according to the specific material and manage it via the associated inLab CAM software. Intelligent spare tool management helps to achieve optimal tool service life and failure safety. Additional user friendliness and user safety is assured by the color coding for material types on each tool and tool magazine in the CAM software.

Easy Clean Concept:-

The high-quality interior design of inLab MC X5 includes smooth surfaces and rounded contours. This reduces deposit amounts making the machine easy to clean. The intelligent suction concept, coverable tool magazine and software-supported cleaning system are all designed to make your work easier.

More convenience with Touch Remote Control

You can now have a complete view of the machining status of your inLab MC X5 anywhere, anytime. With the “touch” optimized inLab CAM software you can navigate through the machine configuration and service functions on a tablet PC quickly and with just a few clicks.